At Creax we care about the bigger challenges we face in society. In our Friday afternoon brainstorm sessions, we like to explore how we can tackle some of these issues and inspire anyone looking for solutions. Reading that Tesla is struggling with the high cost of electric vehicles, we had a short brainstorm on making cheaper electric cars.

Electric vehicles (EV’s) are the inevitable future of transport and mobility. With the reduced CO2-emissions and the potential for renewable energy as the main driver, EV’s are becoming more and more popular. Yet, the high purchase costs compared to traditional internal combustion engine (ICE) cars are still delaying full implementation.

However, due to lower fuel- and maintenance costs, the total cost of ownership (TOC) of EV’s is substantially lower than traditional cars. This means that in the long run EV’s are already cheaper than traditional cars. Despite this, many people still can’t afford the purchase price of an electric car.

To achieve faster adoption, electric cars need to become cheaper. As many people still have other concerns like charging times and range anxiety, EV’s especially need to become cheaper than fuel-powered cars.

The challenge car manufacturers are currently struggling with is how to achieve this goal. Therefore, let’s have a look at some basic rules of cost-cutting and how they can be applied to a standard EV car.

Rule#1: Introduce cheaper materials and technology

Probably the easiest way to decrease the cost of a product is to apply alternative, cheaper materials and technologies. Sure, performance might suffer a bit, but for a lot of consumers, this is perfectly acceptable when it results in a substantial price drop. Not everyone wants to drive a Porsche, Ferrari, or in the case of BEV’s (Battery electric vehicle) a Tesla.

The first potential gain of course is in the battery pack. This is without a doubt one of the more expensive components of a BEV.

The cost of a battery pack is not only driven by the battery cells inside them, but also by the components needed to make it work safely and reliably. We can save a lot of money by switching from the now most commonly used battery chemistry called NMC, to an alternative LFP based chemistry.

This chemistry is often neglected due to its lower energy density, meaning that an LFP based battery pack with similar capacity as an NMC based pack will weigh more. That said, LFP chemistry has many advantages, for example: it is safer, so you need less mechanical and electronic protection and it’s more robust, so you don’t need expensive liquid cooling. The resulting pack has thus less non-battery-related mass, which partly compensates the higher weight of the batteries.

Additionally, LFP batteries are long-lasting and don’t use any toxic or rare elements or cobalt. Best of all, they are a lot cheaper, at 60 €/kWh vs 100 €/kWh for NMC battery cells.

A hypothetical 40kWh module battery pack using modern LFMP batteries (a high voltage variation of LFP) could be obtained for less than €4000 and could easily provide a real-world range of more than 250km to our cheap BEV.

Apart from a cheaper battery, there are plenty of opportunities for cheaper materials in the exterior and interior of the car. A suitable component for a material replacement is the car bumper, which is typically made from reinforced plastic and painted to match the body color. This makes it quite expensive; especially if it needs replacement. Therefore, we believe a cheaper bumper can be made from less expensive materials, without compromising the performance to withstand impact.

EPP-high impact-foam is a material used in the shipping and packaging industry. It is cheap, lightweight, and can withstand large impacts. Also, the material can be formed quite easily into complex shapes, making it very suitable as a bumper material. It is also widely used in protective gear like bicycle helmets and sports harnesses.

Rule #2 Reduce the number of parts

Sometimes, instead of making each part or component less expensive, we can even eliminate it completely. This is known as trimming. The fewer parts your product needs, the cheaper it becomes. Trimming can be done by considering the system as a whole, moving, combining, and integrating functionalities into other parts of the system.

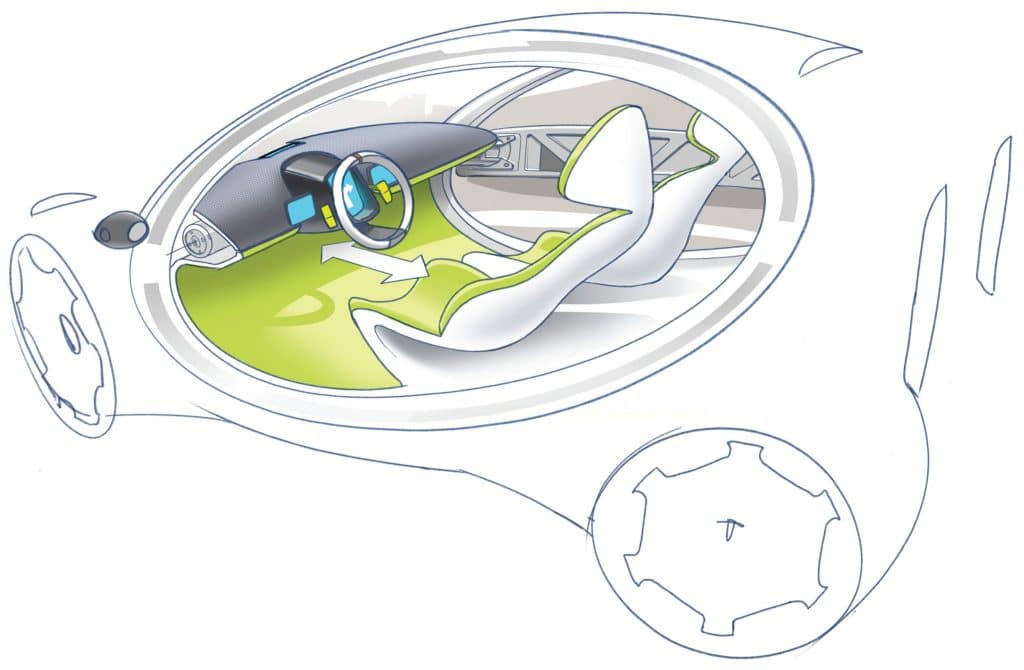

In this example, we focused on the cockpit of the car. By moving all the functionalities and the adjustment possibilities into the steering wheel itself, we probably make this unit more expensive, but at the same time reduce the cost of the other components, since they don’t have to be so complex. The seats themselves are fixed inside the interior. The pedals are replaced by paddles on the steering wheel and the central console can be ditched altogether.

Rule #3 Design parts for multiple use

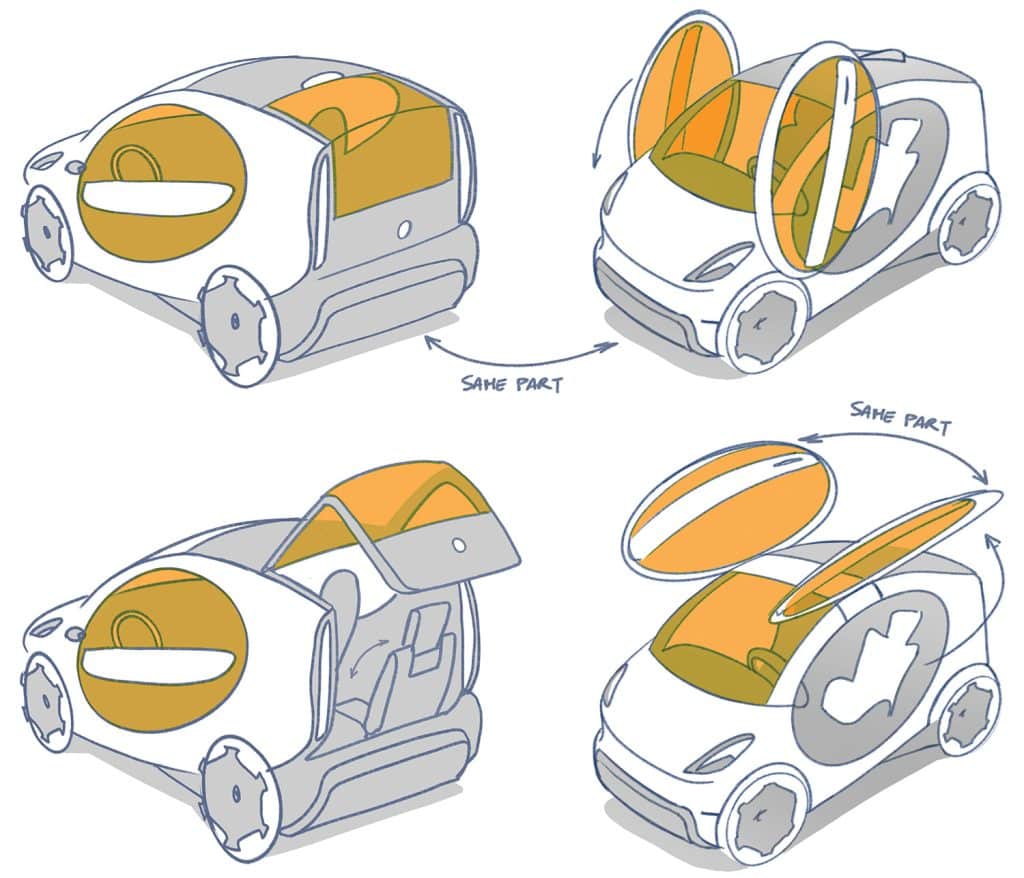

Alternatively, reducing the number of different parts will also result in a cost reduction, as the economies of scale can be leveraged to your advantage.

What if we could use the exact same door for both the left and right sides of the car? Such questions can result in quite surprising outcomes, as can be seen in the odd elliptical shape of the passenger doors. Because the design is symmetrical, there is no need for a left or right variant anymore and the door can be installed on both sides. As for opening them, 2 options are available: either they can pivot open at the front or be mounted in a gullwing-style fashion.

The bumpers we talked about earlier can also be designed to be assembled in the front of the car as well as in the back. This further reduces the number of different components and drastically decreases the total cost of the car. The same principle can also be applied to the rear-view cameras, the passenger seats, and probably some other components, like the taillights.

Rule #4 Faster production

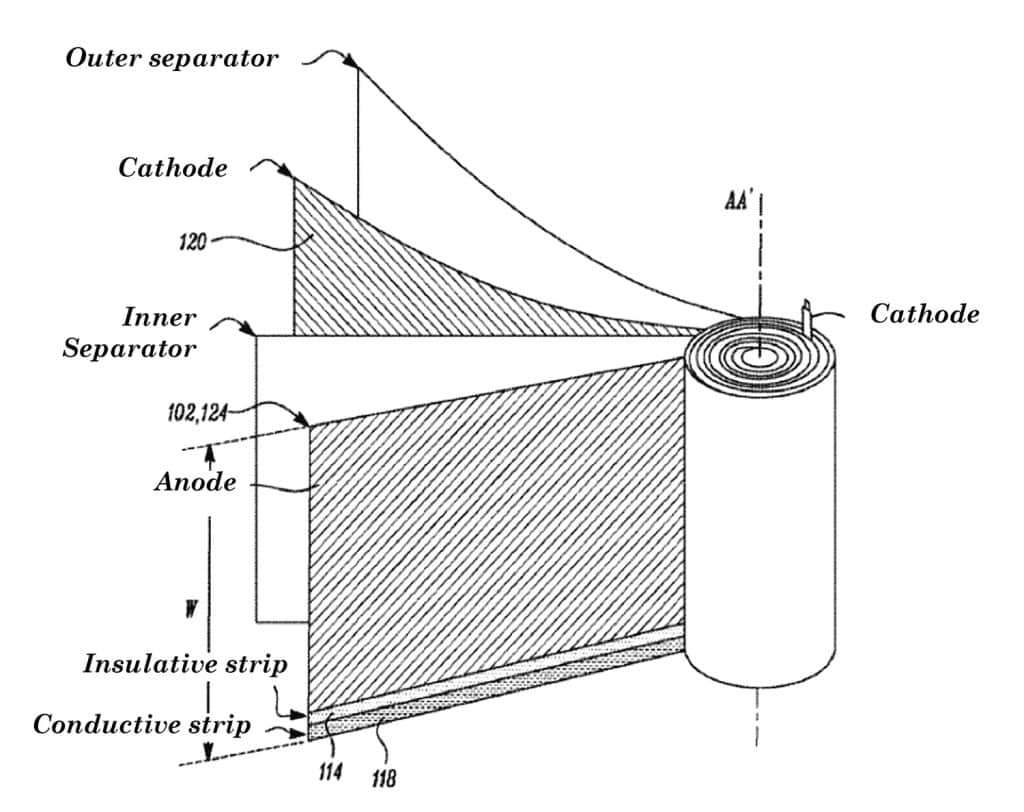

Faster production often introduces new challenges but will also yield significant cost savings. This was recently illustrated by Tesla with the new tab-less battery design. The resulting thermal advantages of this new battery architecture allow for a much less complex assembly. More importantly, it allows for faster production of the battery cells, a real bottleneck in the production of electric cars.

Conclusion

As shown in the example, applying these basic cost reduction principles can result in some surprising redesigns and the introduction of new materials and technologies.

In a cost-cutting exercise, it is important to have an open mind and question everything. Solutions can often be found in other industries or areas, even if they are not always obvious. Therefore,

creativity may be the most important tool in your engineering toolbox.