In our modern economy, industries rely on a continuous input of resources to keep their daily activities running. At the same time, they create an unstoppable output of waste streams. It seems obvious that the reconciliation of these two opposing needs – a steady input of resources versus the constant disposal of waste – is one of the major concerns for innovators.

All industry domains experience generation of waste streams. These material flows are often seen as problems and are handled to limit their impact or, in the best case, to be recycled. The waste streams of one industry domain however, often have value in other industry domains. We believe in looking at waste as a resource with market opportunities across industry boundaries, and not merely something to be recycled or discarded.

This way of thinking requires an innovative approach and the extension of the search for solutions to other industrial domains. Get inspired by some industry examples that show how the threat of waste streams can be turned into a business opportunity.

1. Don’t search too far, integrate

Waste streams that are created on-site are often sent to waste disposal sites without questioning their possible value. Many opportunities to integrate side-streams within the existing process lines are wasted.

Agricultural products typically have high quality requirements, resulting in a lot of waste through the sorting out of deformed and unclean parts of foodstuffs. In the cultivation of mushrooms, for example, the stem bases, which make up a quarter of the total weight, are usually discarded. The R&D department of Scelta, a Dutch mushroom producer, came up with an innovative approach to reduce their mushroom waste. They developed a dedicated line to transform the mushroom stem bases into a mushroom extract. Unilever, one of its customers, uses the natural mushroom concentrate worldwide in its soups and sauces.What was once a waste material is now turned into an added value product. By switching the mindset, Scelta could make more food out of food and enter a previously unexplored market segment

2. Add extra value to allow high end uses

Waste streams often seem invaluable, and without adding extra value no other company will see the opportunities of the waste resource. Smart solutions for waste validation often comprise a supplementary production step to transform the waste into a valuable product. By making a small investment in the waste stream, a sudden shift of market opportunities to high end markets can occur.

Miniwiz, a Taiwanian waste innovator & product design company, makes building materials by re-engineering used plastic bottles. By designing a dedicated remoulding process for PET bottles they make lightweight, insulating building bricks. The Polli-brick® units are used to make durable architectural panels and walls.Every production site has many different waste streams. Investing in these waste streams is often considered useless. However, by adding a simple process step considerable value can be added and the waste can become a high value product. Although remoulding plastics seems very simple, at Miniwiz it opened up a whole new market.

3. Don’t wait till waste disposal costs shoot through the roof

The largest cost associated with waste streams is usually their disposal cost. Often companies have a passive approach, they wait until the rise of waste disposal costs & new regulations force them to look for new solutions. However, by being pro-active you can take a head start on your competitors and replace disposal costs by additional revenue.

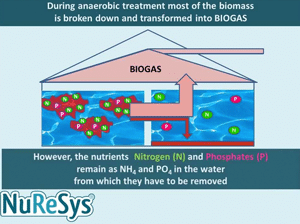

Wastewater is a waste stream that typically has high disposal costs. Penalties for the release of nutrients, like phosphorus and nitrogen, into the environment are high. Conventional wastewater treatments degrade nitrogen and precipitate phosphorus with aluminum or iron salts, thereby producing a solid phosphorus waste. A Belgian technology company, NuReSys, has developed a novel technique to recover both nitrogen and phosphorus out of wastewater instead of degrading it. By treating the effluent with a magnesium ore, they can produce a high-grade mineral fertilizer.The development of this novel technique not only eliminates the high disposal costs but also uses wastewater as a valuable nutrient source. By being pro-active, NuReSys takes the lead to reduce disposal costs and at the same time produce new revenue streams.

4. Waste is everywhere, expand your scope

A company has many waste streams, and all of them have potential to be marketed. The initial scope of waste stream validation is often limited to solid waste. However wastewaters, off-gasses and waste heat can have all have additional value.

In the port of Terneuzen, Yara, a Norwegian-based chemical company, has a facility that produces ammonia. In this process, CO2 is generated as a byproduct, polluting the environment with greenhouse gasses. Yara searched how to deal with the CO2 waste. Unable to reduce their CO2emissions, they searched for valuable applications of the gas instead.

In 2008 they came up with an innovative way to validate the off-gas. They funded a joint venture with a construction corporation to build a greenhouse-park next to their production site. In the greenhouses, the hot gas helps to provide a good growing environment for the crops and furthermore boosts plant growth due to the carbon fertilization effect.This example shows that all waste streams, whether gaseous, liquid or solid can have added value. It shows that mapping the potential of these streams and comparing them with the specific needs of neighboring companies can bring about innovative solutions to market these valuable waste sources. Yara validated the heat and the nutritional value of their gas sidestream to expand to new applications.

Do you also want to find new applications across industry boundaries for your waste stream?

Have a look at our market development service.

References

- www.celtamushrooms.com

- https://www.miniwiz.com/solution_detail.php?id=5

- www.nuresys.org/content/technology

- www.bioparkterneuzen.com

- https://dbt.ugent.be/pdf/reststromen_eindpublicatie.pdf

[1] Trends, 46stejaargang, 2 april 2020